1.The major structures are manufactured

from Meehanite cast iron, stress relieved and combined

with scientific rib reinforcement to ensure deformation-free

operations.

2.Increase width on the column bottom with box-type structure provides maximum

stability especially when performing high speed cutting.

3.Linear ways on three axes assure high feed rates and extremely smooth motion.

4.Extra wide span between linear ways greatly increases machine stability.

5.The structural parts are analyzed and designed by the advanced Finite Element

Analysis. It provides a detailed analysis for structural stress/strain conditions,

and ensures excellent machine rigidity and lifetime stability.

6.Linear guide ways:

The machine employs 45mm wide ball-type linear guide ways. (Optional)

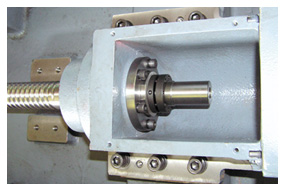

7.Precision ball screw:

Three axes are transmitted by high precision C3 grade ball screws, preloaded,

hardened and ground-assuring dependable feed accuracy.

8.Choice of 30,000 rpm high speed spindles are designed for high speed machining

requirement.

9.Extra wide column bottom and base ensure simplified machine structure for space

saving.

10.The three axes ball screws are directly coupled

to servos through backlash-free couplings. This

ensures dependable positioning accuracy. High precision

class C3 ball screws are preloaded to eliminate

thermal strain.

The structural parts are analyzed and designed

by the advanced Finite Element Analysis.

The machine employs 45mm wide ball-type linear

guide ways.

Three axes are transmitted by high precision

C3 grade ball screws, preloaded, hardened and

ground-assuring dependable feed accuracy.

Choice of various high speed spindleá

Belt Drive Spindle

Choice 8000,10000,12000RPM.Spindle taper BT-40

Direct Drive Spindle

Choice 10000,12000,15000RPM. Spindle taper BT-40

Build in Type Spindle

Choice 24000,30000RPM. Spindle taper HSK-50E

|

Carousel type magazine

The carousel type magazine is standard equipment.

It carries 16 tools for various types of machining

applications.Fixed type tool selection for quick

tool changing that reduces non-cutting time.

|

Arm type magazine(Optional)

The magazine is driven by a precision cam for rapid

and stable tool change motion. Tool loading capacity

provides 20 or 24 tools to choose from. Bi-directional

random tool selection provides quick tool changing

that reduces non-cutting time.

|

Directly coupled servomotors:

The three axes ball screws are directly coupled to

servos through backlash-free couplings. This

ensures dependable positioning accuracy. High

precision class C3 ball screws are preloaded

to eliminate thermal strain.

|

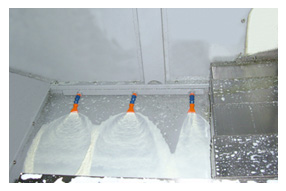

Coolant flushing device(Optional):

Three coolant nozzles are provided on both sides

of the tableá featuring high pressure flushing

to remove chips from the table.

|

4th CNC rotary table(Optional)

The 4th CNC rotary table features high positioning

accuracy and maximumástability during cutting. It

is ideal for various types of workpiece machining.

|

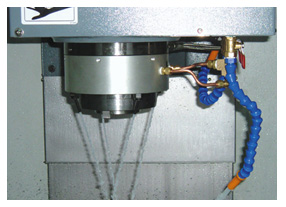

Spindle splash ring (Optional):

The spindle splash ring is available only for models

with arm-type magazine. The device not only effectively

removes chips on work piece but also increases

work piece cooling efficiency.

|

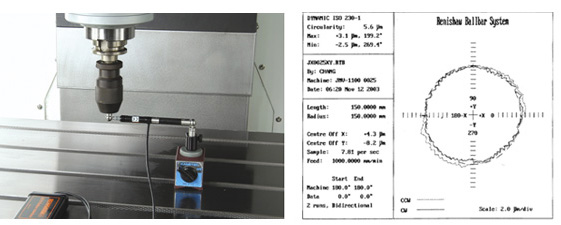

Ball bar test:

Through ball bar testing the circularity, geometry

error and backlash can be accurately obtained allowing

the machine to be adjusted to the best possible

accuracy.

|

Laser inspection:

An advanced laser instrument is employed for inspecting

and compensating linear accuracy and pitch error.

This ensures optimum axis travel accuracy.

|

Heat exchanger for controller cabinet:

To maintain a constant temperature inside the control cabinet, the machine is

equipped with a heat exchanger. It provides effective protection for the

controller and electronic components. The high performance heat exchanger

features high efficiency heat exchange and power saving.

|

Spindle oil cooler:

It prevents spindle thermal

deformation due to oil temperature variation while

ensuring high machining accuracy, especially at

high spindle speeds.

|

Inspection Procedures:

1. Geometric Accuracy Inspection.

2. Spindle Balancing Adjustment.

3. Full running test 24 hours before delivery.

4. Practical work piece machining test.

5.Water tank leakage test.

6. Machine functional test

|